Features:

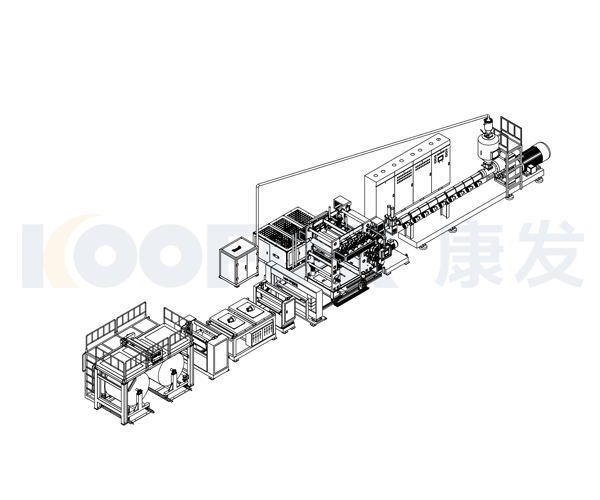

◎ The average power consumption per ton of finished sheet can be as low as 200kWh.

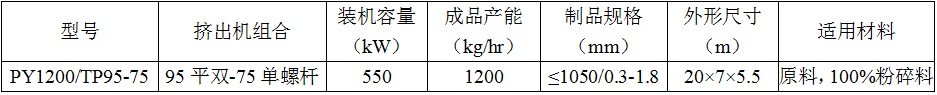

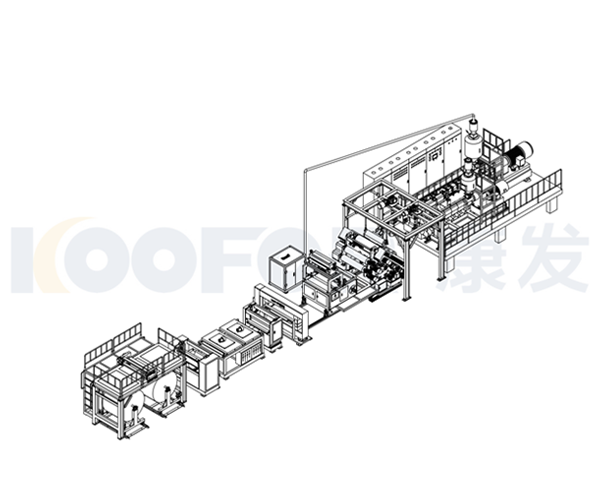

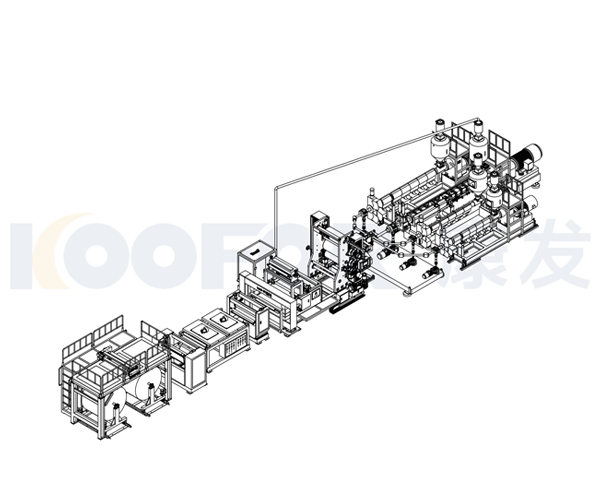

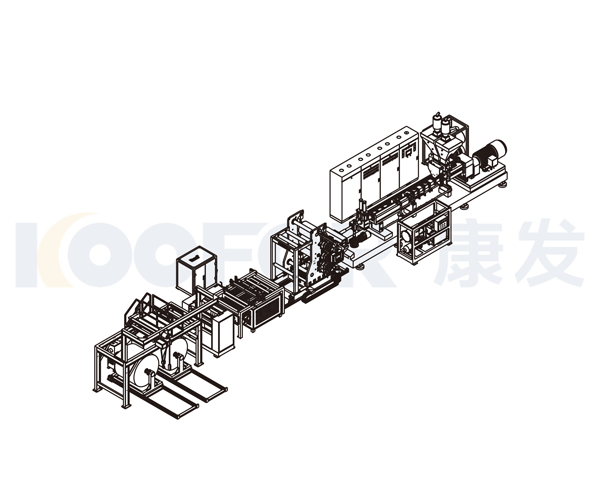

◎ This equipment is composed of a parallel twin screw and a single screw extruder, which can produce and process AB,ABA structure sheet, suitable for processing American meal box.

◎ This machine is suitable for adding 52% talc granules. Mixing uniformity, sheet rigidity, surface no precipitation, low cost.

◎ The main machine is equipped with parallel twin screw extruder in the same direction, multi-stage exhaust, no drying, better plasticizing mixing effect, reduce labor intensity.

◎ Melt metering control, closed loop with extruder, extrusion pressure more stable. Three roller arrangement: horizontal structure, suitable for high filling formula of sheet shaping.

◎ The whole line adopts man-machine interface display, equipped with temperature module management, one-button speed up and other functions, more convenient operation.

◎ The mould adopts on-line manual screw adjustment, which greatly saves the time of adjusting the width of sheet material and does not leak material.

◎ The machine is equipped with lateral precision feeding device, which can produce different colors and properties of the sheet. The net changer adopts the double column circular long acting filter, the single net changing time can be extended to 50-100 hours.

◎ Large winding diameter (up to 1500mm), equipped with frequency conversion drive, constant tension control, so that sheet winding more orderly.

21pla.com

21pla.com