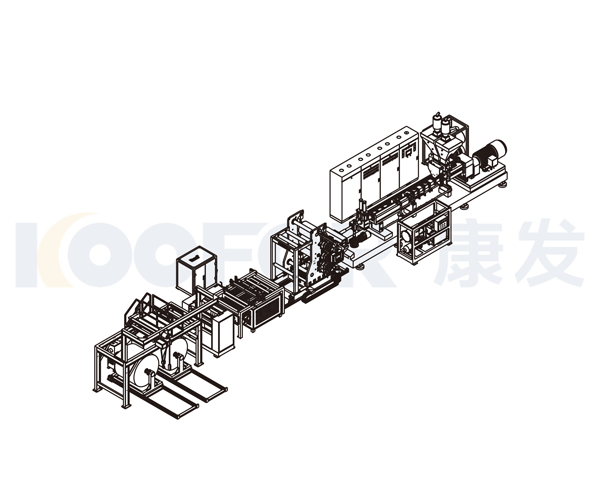

Features:

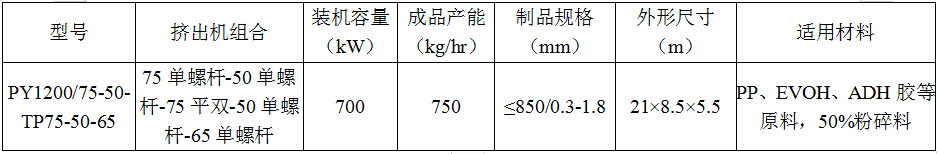

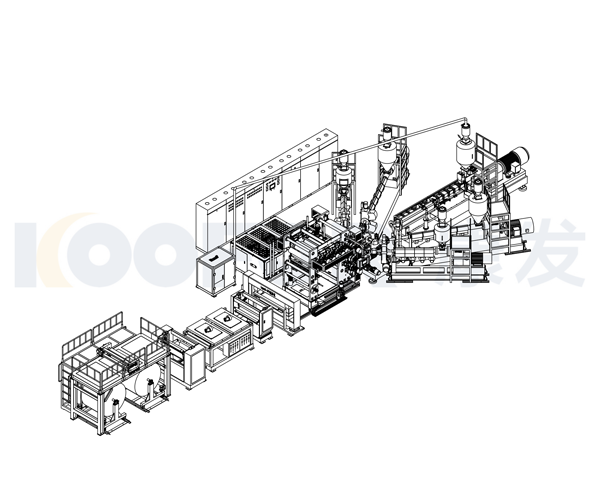

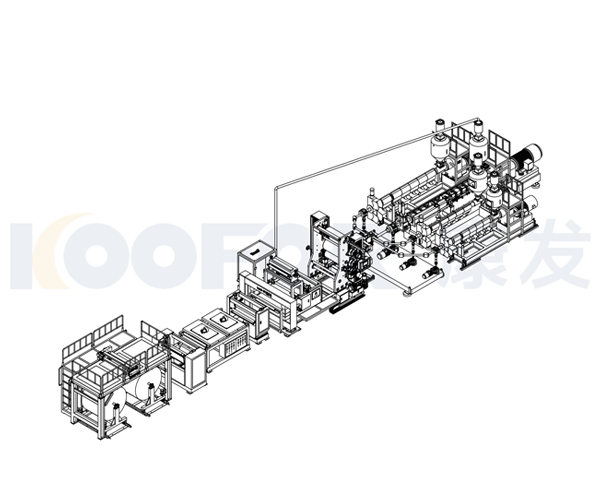

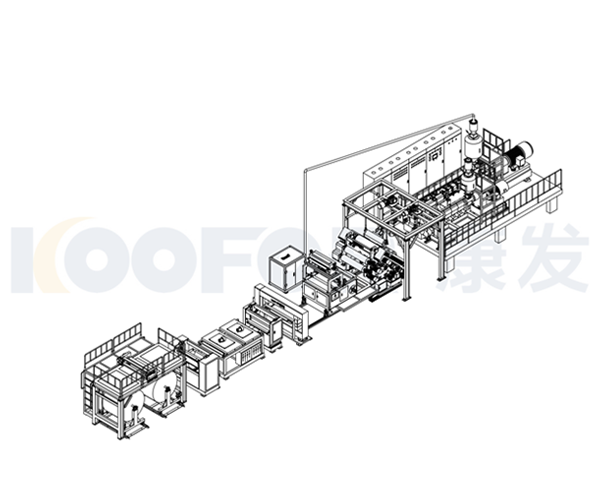

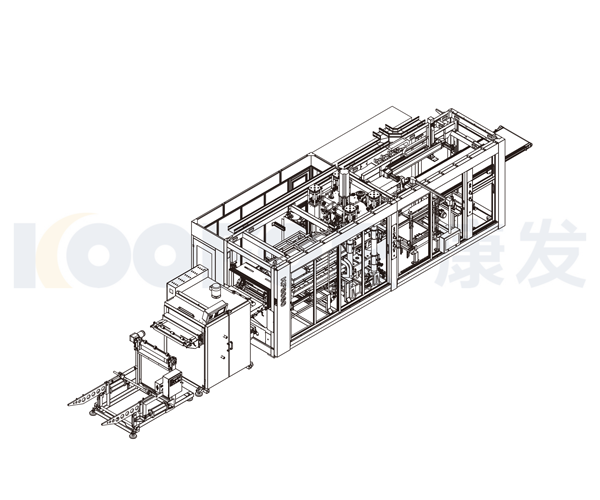

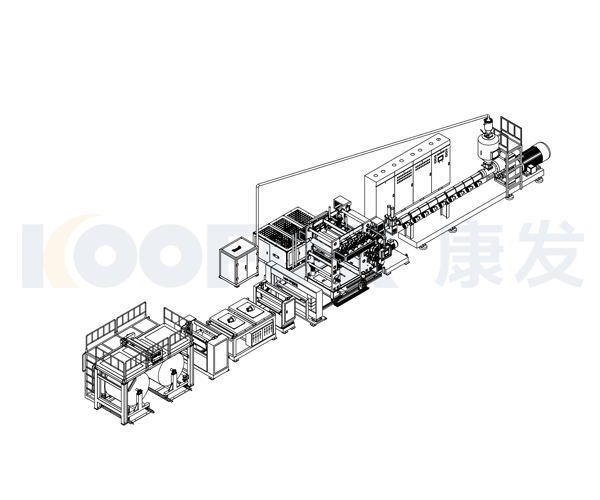

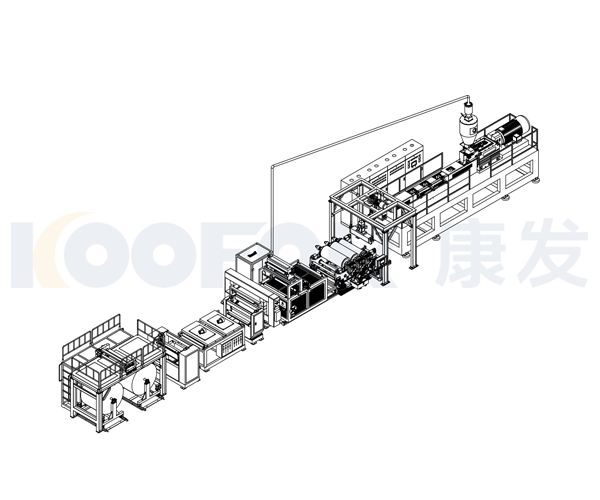

◎ The main machine is composed of 5 extruder units of "75 single screw -50 single screw -75 flat double -50 single screw -65 single screw", which can produce seven layers of EVOH co-extruded high barrier performance sheet. The product structure is ABCDCBE (D is EVOH, C is ADH glue, B is crushing material, A and E are monochrome or two-color PP).

◎ Adopt precise distribution technology, measure and distribute according to the proportion of structure; Fixed runner, more precise stratification, more stable pressure. EVOH layer thickness error is controlled within ±0.01mm.

◎ Melt metering control, closed loop with extruder, extrusion pressure more stable.

Three-roll arrangement: Adopt upright structure, with precision nine-roll calensing technology, so that the sheet is fully cooled and shaped, the thickness is more uniform and controllable.

◎ The whole line adopts man-machine interface display, equipped with temperature module management, one-button speed up and other functions, more convenient operation.

◎ The mould adopts on-line manual screw adjustment, which greatly saves the time of adjusting the width of sheet material and does not leak material.

◎ The machine is equipped with lateral precision feeding device, which can produce different colors and properties of the sheet.

The net changer of double extruder adopts double column circular long-acting filter, the single net changing time can be extended to 50-100 hours.

◎ Large winding diameter (up to 1500mm), equipped with frequency conversion drive, constant tension control, so that sheet winding more orderly.

21pla.com

21pla.com