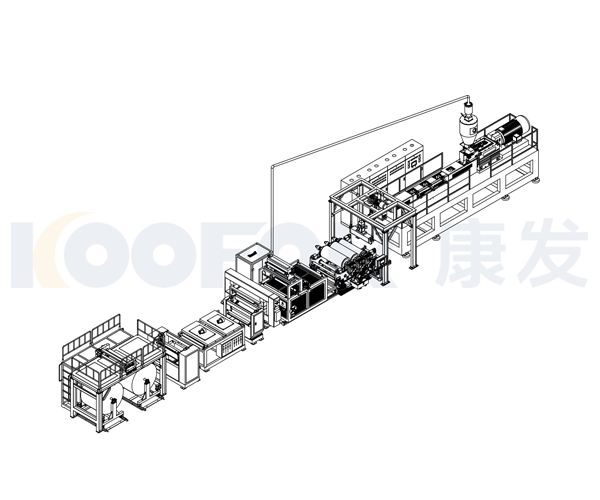

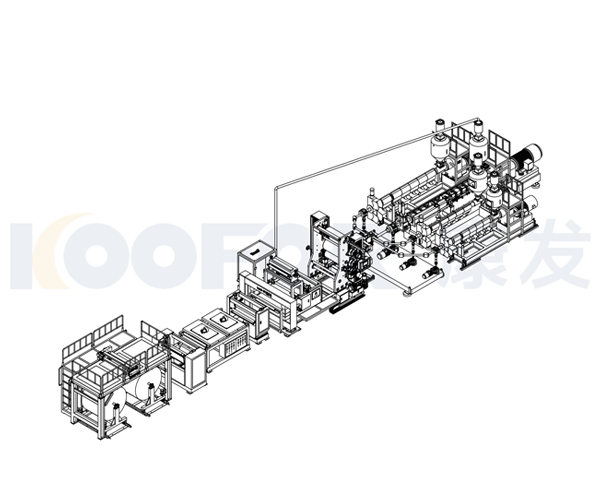

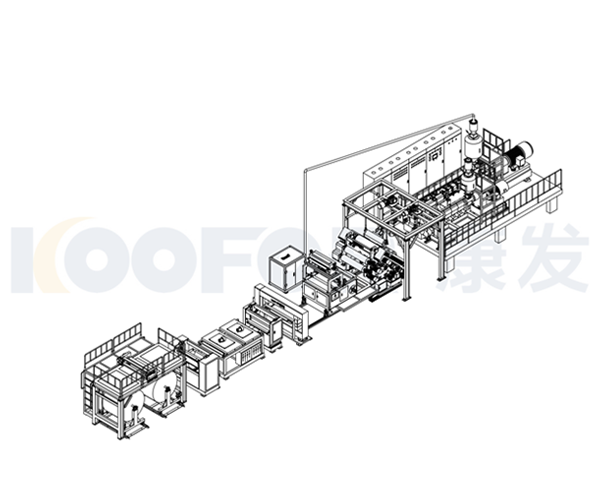

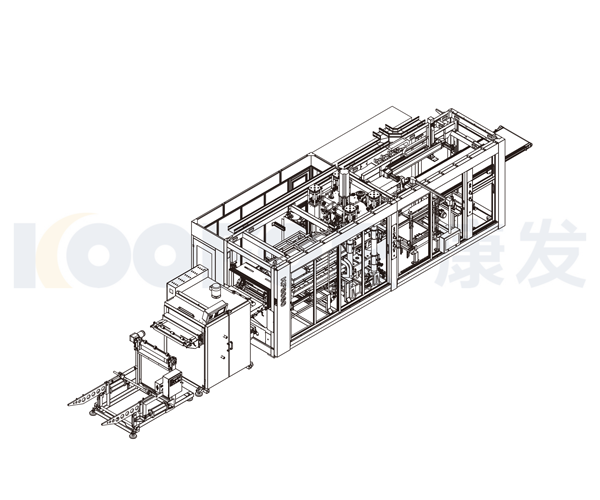

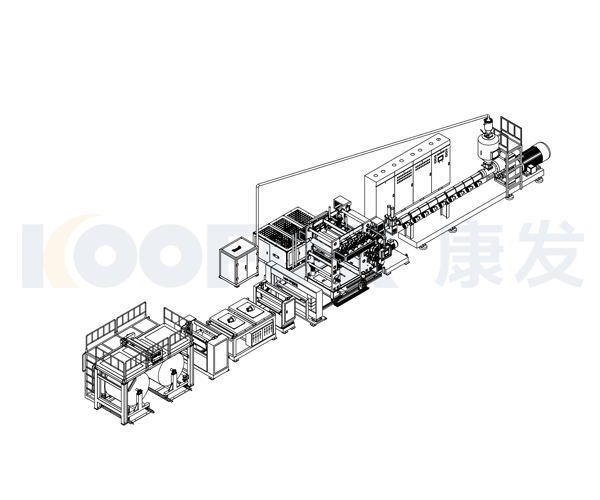

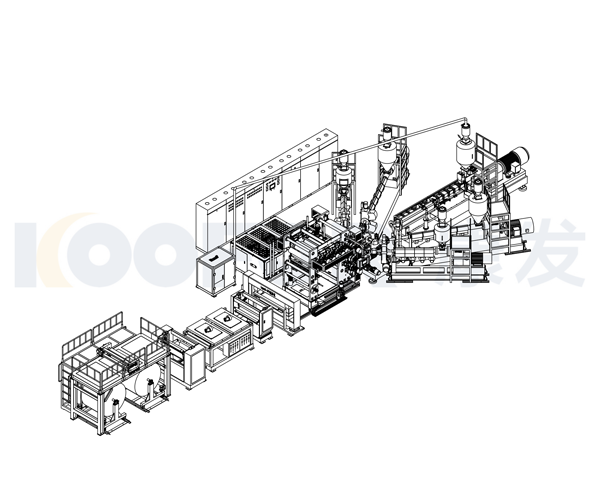

Features:

◎ The average power consumption per ton of finished sheet can be as low as 250kWh.

◎ It is suitable for extrusion production of 100% pulverized material, with wide channels and low price, supporting environmental protection industry.

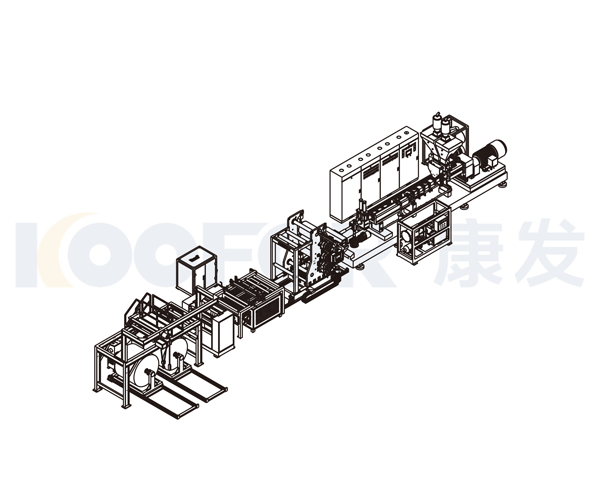

◎ The main machine is equipped with parallel twin screw extruder in the same direction, multi-stage exhaust, no drying, good plasticizing, viscosity drop is only 0.04.

◎ The machine is equipped with lateral precision feeding device, which can produce different colors and properties of the sheet.

The energy consumption of the whole machine is 60% of that of the conventional single screw extruder.

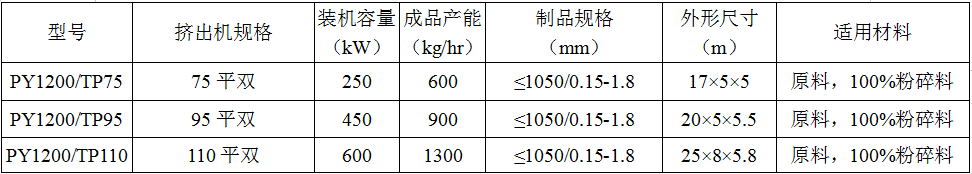

◎ According to the equipment model, the output is as high as 600kg/hr, 900kg/hr, 1300kg/hr, and the products do not change color, good toughness.

◎ The whole line adopts man-machine interface display, equipped with temperature module management, one-button speed up and other functions, more convenient operation.

The net changer adopts the double column circular long acting filter, the single net changing time can be extended to 50-100 hours.

21pla.com

21pla.com